Making Alphorn Tuning Tubes / Hand Tubes

for Seattle Opera's Daphne Performances

General Information

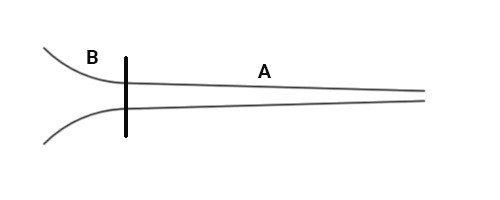

A Simplified Alphorn Width Profile

An alphorn is conical throughout its entire length.

About 80% (very approximate) is linearly conical (section A)

About 20% is an accelerating flare (bell) (section B)

Hand tubes lie in the A area of the alphorn (linearly conical).

Making the conical bore is considerably more difficult that making a cylindrical bore, which can be done with a long fixed-width drill bit. The conical bore requires either:

- Hand gouging (cheapest for tools, but more labor intensive)

- CNC machine (very expensive for tools, and requires initial labor in programming tasks)

CNC Machined Tubes

For a quick view of a CNC machine making a perfectly conical gouge, see:

- Alphornbau Biermaier (YouTube): https://www.youtube.com/watch?v=P6gzW6uArM0

The CNC machine is seen in use between times 1:17 – 1:37 - CNC machine costs vary widely.

Industrial/Production machines can run ~$10k – $30k,

High-End/Custom machines can run ~ $30k – $120k and up.

Hand-Gouged Tubes

For the hand-gouged method (still using tools, hand tools, drills with sanding bits, etc.)

- Alphorn - Der Bau eines Alphorns (YouTube): https://www.youtube.com/watch?v=7ZaNfz142Oo

- A linearly conical section is shown between times 5:21 — 9:24 and 14:25 — 14:45

See the whole process of making an alphorn in this video from Bachmanns Alphornmacherei in Eggiwil, Switzerland, where I purchased my alphorn. Note: You do not need to unserstand Swiss dialect to appreciate the visuals!

- Die letzten Alphornmacher im Emmental (YouTube):

https://www.youtube.com/watch?v=UTyC7DfWeSo

Links to these and other alphorn-making videos are here: https://alphorns.com/alphornmaking.html

Comparison of Alphorn Costs

A CNC machined alphorn can cost as low as $1300—$1500. For example, see the "entry level" Thomann Matterhörnli in F (https://www.thomannmusic.com/thomann_matterhoernli_in_f.htm). While the CNC machines are expensive, labor costs in making an alphorn are drastically reduced. One estimate is that a CNC machined alphorn might take a total of around 20 hours to build. A hand-made alphorn takes roughly 80 hours to build.

A hand-made alphorn from Walter Bachmann costs CHF 3125 (Swiss francs) for an F# horn, CHF 3200 for an F horn. If you want to play your alphorn in the U.S. and in Switzerland, purchase the F# horn and add the long F tube (F-Teil lang) for another CHF 600, for a total of CHF 3800 (prices from Bachmann's "Alphornpreisliste" accessed 27. Jan 2026 from the link at

https://www.alphornmacherei.ch/alphorn-preisliste/ ).

At today's exchange rate (27. Jan 2026), CHF 3800 =

$4963. You will also need the alphorn bag (Etui), maybe have the bell painted, and maybe an extra alphorn mouthpiece (one mouthpiece comes with the purchase of the alphorn). At around $5000+ the cost is considerably more than a CNC machined alphorn.

My Journey Into Alphorn Tube Making

Making alphorn tubes is a regular activity of every alphorn maker. Each maker uses a different set of tools and uses different techniques. They already have templates for consistent reproduction of each part. I started from scratch, knowing only what I saw on YouTube and on a visit at Walter Bachmann's workshop in 2021.

I decided to try making my own alphorn tuning tubes after hearing about the Seattle Opera's concert presentation of Richard Strauss's opera Daphne. The Alphorn parts required alphorn tunings in G, A-Flat and A. I already had an A-Flat tube. Could I make the tubes for the G and A parts?

I acquired necessary tools along the way. One tool I lack is a table saw, needed for trimming boards to appropriate widths for gouging and turning. Local alphorn player and seasoned professional French Horn player Ryan Stewart generously operated his table saw to make all the needed cuts while I watched :)

The A-Tube

It took me 3 builds to make the A-Tube correctly, in tune, from the right material. Thanks to a recent refresher course I audited in the Physics Department at the University of Washington — “The Physics of Music” — I could calculate the approximate length the A-Tube should have. [For more about my history of making musical instruments from primitive materials, see: https://alphorns.com/natural/index.html.]

Build 1:

A-Tube from 2 maple dowels (connected together with mortise & tenon — red square center below). This build was also useful it learning how to create the the narrow channels for the O-Rings for proper sealing of the tube with the middle tube of my alphorn — red rectangle left.

I used step-drilling to create a rough conical interior bore, smoothed out the steps with a rasp and a sandpaper-wrapped wooden dowel. Then I finished the exterior on a lathe.

Hard maple is not a great tone wood for an alphorn tube, but this first build was useful in determining the length I needed to produce A-tuning with my Bachmann alphorn. I already had the maple dowels, so there was no extra cost for me here.

Build 2:

A-Tube made from Basswood with conical gouging of 2 lengths — the traditional way of building alphorn tubes. The red rectangle shows the long glued seam of the two halves.

Basswood is not a great tone wood for an alphorn tube, but its relative softness helped me learn how, for my first time, to gouge out the inner channels. Basswood is also not expensive. I was also able to recheck the length/tuning accuracy to produce the A harmonic series with my alphorn.

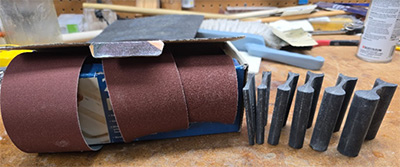

My Tools:

Below left, Swiss Made (Pfeil) gouges – for hand gouging the tube troughs

Below right: Round sanding forms + sandpaper rolls in various grits in the same width as the sanding forms.

Below left: Calipers with a depth gauge to check trough depth every inch or two along the path.

Below right: Metal rails to define the conical edges and keep the gouges inside the lines :)

Build 3:

A-Tube from 2 blocks of Engelman Spruce (from Canada), purchased from StewMac in Ohio.

These are “Guitar Brace Blanks” generally carved into small pieces of wood to provide structural support and to shape a guitar’s tone, projection and resonance.

I bought 2 pieces of Item #103697, Engelmann Spruce, 2", approx. 24" x 2" x 1" (true measurements). These were the perfect sizes for building the A-Tube using 2 long pieces with half of the conical bore carved lengthwise from each piece. I needed less than 22 inches in length, and these were 24 inches. I needed a maximum diameter of just under 2 inches. The two 1" depths together gave me 2". The 2" width was perfect. They were relatively affordable, but not inexpensive. My order totalled $52.09 for the 2 blanks plus shipping. This build was very successful, producing the...

A-Tube used in Daphne

2 halves glued together, turned, fitted with olive wood mouthpiece adapter.

The G-Tube

I had difficulty finding spruce lumber longer than the 24" blocks available from StewMac. For the G-Tube I needed 36" length stock. I found a nice and affordable Douglas Fir board at Dunn Lumber, Shoreline, WA, and built this beautiful G-Tube:

The tube had excellent tuning. However, a couple partials used in the Alphorn calls in Daphne were a wee bit “squirley.” With the assistance of AI, I learned that spruce lumber might be available from Dunn Lumber in Lynnwood, WA (I did not find it at the Shoreline location). And AI was correct! Dunn Lumber in Lynnwood had an entire section of spruce lumber! They had 1 x 4, 1 x 6, 1 x 8, 1 x 12 boards in lengths from 8 ft to 16 ft.

These are Gorman Elite boards from Gorman Bros., Kelowna, British Columbia, Canada: https://www.gormanbros.com/products/gorman-boards/

G-Tube halves ready for gluing and turning:

Turning:

So now I had all the 3 Tuning Tubes for Daphne

Left to right: G tube, A-flat tube, A tube. I also made the stand for use at the performances.

So, there you have it! Except for some final tweaks :)

Final Tweaks

Mouthpiece Adapter

I needed to make one small adjustment on each of the G-Tube and A-Tube mouthpiece adapters. The mouthpiece wasn’t firmly seating in the adapter — there was a slight wobble. Mark had earlier introduced me to Jim Weaver, a nearby Edmonds resident who made custom French Horn mouthpieces and had a lot of experience working with metal. He is also the inventor of the “Counterpoint Opus” tandem bicycle. I spent several hours with Jim at his home shop learning about all kinds of tools and techniques that helped me with my wood tube projects. One of the most useful tools for remedying the “wobble” of the mouthpiece was the “tapered reamer.” I purchased 3 sizes and tried each on a variety of projects.

I just turned the reamer gently by hand inside the adapter until the mouthpiece shank found a snug fit.

Alignment Marks

During Mark’s warm up before the Dress Rehearsal on Jan 14, a partial on the G Tube was not immediately slotting. That’s when I recalled the alignment dots on each tube of Bachmann’s alphorn. When you insert a tube into another one, you are to align the dots on each tube. It’s not as though the alphorn doesn’t work if you don’t align the dots, but I’m guessing (I haven’t asked Walter) that the dots represent “sweet spots” where the alphorn plays very stable notes.

I rotated the G-Tube about 1/4 of a turn. Mark landed on all the notes perfectly. I used a black Sharpie to mark the dot on the tube. We did a quick check of the short A-Tube, but during the Dress Rehearsal, Mark had a similar issue with one of the partials. Mark also noticed a slight wobble again in the way the mouthpiece seated in the A-Tube adapter.

So, just before the first performance on Friday, 16 January, Mark and I met shortly after 6:00 pm in the hallway where the lockers are. I brought my 3 tapered reamers, a small brush, a paper bag to collect wood debris, and a Sharpie. After 2 or 3 rotations of the A-Tube, we found a “sweet spot” and marked it. Mark wanted to recheck the G-Tube. We made a couple rotations, found and marked a better “sweet spot.” At Friday’s performance, Mark nailed every note of all 5 calls with absolute precision and clarity!

| Alignment line on the A Tube | Alignment dot on the G Tube |

|

|

The Alphornist, Seattle Opera Staff & Reheasals

On 1 October 2025, Jeff Fair, Principal Horn, Seattle Symphony Orchestra, introduced me (via email) to Michaella Calzaretta, Chorus Master & Head of Music Staff, Seattle Opera. Over the following 10 weeks, Michaella kept in contact with me about the logistics of using the Alphorn and rehearsal schedules for Daphne.

Jeff Fair informed me that fellow hornist Mark Robbins, Associate Principal Horn, Seattle Symphony Orchestra, would be the one to play the alphorn calls. Mark came to our home 4 or 5 times between 2 November 2025 and 4 January 2026 to try out the Alphorn calls on my alphorn with the 3 tuning tubes. Considering that Mark had little previous experience playing an alphorn, he caught on very quickly!

I attended all rehearsals at McCaw Hall:

Friday, 9 January 10:00 am to 1 pm and 2:30 pm to 5:30 pm

Monday, 13 January: 1:30 to 4:30 pm and 7:00 to 10:00 pm

Tuesday, 14 January: 7:00 to 10:00 pm

Wednesday, 15 January: 7:00 to 10:00 pm (Dress Rehearsal, I was able to leave after the break)

During the first performance on Friday, 16 January at 7:30 pm, I stayed in my designated area in the back of the stage. During the second performance on Sunday, 18 January at 2:00 pm, I was able to be seated with my wife during the late seating opportunity at 15 min. past the start of the opera. These were two very different visual and audio experiences!!

Throughout all of my interactions with the Seattle Opera, Michaella Calzaretta, Aric Lee and Jay Gosselin rendered fabulous assistance in every aspect of my role as “Alphorn Tech” — to assist Mark in changing the tuning tubes at the appropriate times.